Solar fences are an innovative solution combining renewable energy with effective perimeter control, making them increasingly popular among farmers, ranchers, and property owners. By harnessing solar power, these systems offer a range of benefits that enhance security, reduce operational costs, and promote environmental sustainability.

Key Benefits of Solar Fences

1. Off-Grid Capability

Solar fences operate independently of the electrical grid, making them ideal for remote areas where access to electricity is limited. This autonomy allows for flexible installation without the need for extensive wiring or infrastructure.

2. Cost Efficiency

While the initial investment may be higher, solar fences eliminate ongoing electricity costs. By utilizing free solar energy, users can achieve long-term savings and reduce their overall operational expenses.

3. Environmental Sustainability

Harnessing solar energy reduces reliance on fossil fuels, contributing to a decrease in greenhouse gas emissions. Solar fences align with eco-friendly practices, promoting a cleaner and more sustainable environment. AMAROK

4. Portability and Flexibility

Solar fence systems are often designed for easy relocation, allowing users to adapt their fencing to changing needs, such as rotational grazing or temporary enclosures. This flexibility enhances land management practices and operational efficiency. am.gallagher.com

5. Low Maintenance

With fewer mechanical components and no reliance on external power sources, solar fences require minimal maintenance. Regular cleaning of solar panels and periodic checks of the system ensure optimal performance with minimal effort.

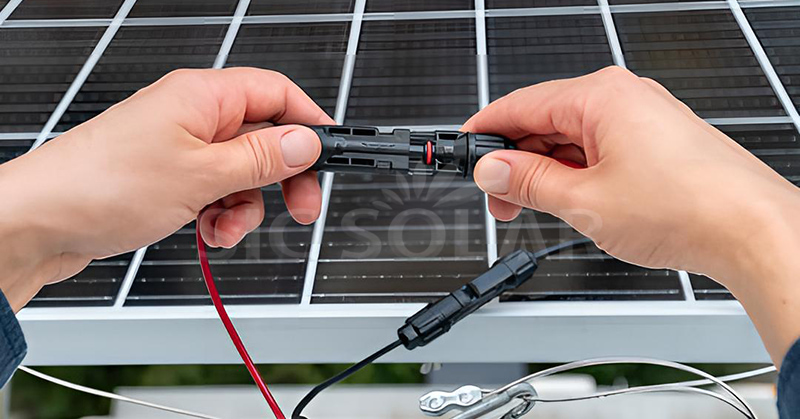

Enhancing Solar Fence Systems with Quality Mounting Solutions

The effectiveness and longevity of solar fences are significantly influenced by the quality of their mounting systems. Robust and weather-resistant mounting brackets ensure that solar panels remain securely positioned for optimal sunlight exposure. Companies like SIC Solar, specializing in the production and sale of photovoltaic mounting brackets, provide durable solutions that enhance the stability and efficiency of solar installations.

Solar fences offer a reliable, cost-effective, and environmentally friendly solution for perimeter security and livestock management. Their off-grid capabilities, combined with low maintenance requirements and operational flexibility, make them an attractive option for various applications. By incorporating high-quality components, such as mounting systems from SIC Solar, users can maximize the benefits and longevity of their solar fence installations.