When planning a solar panel installation, one of the critical factors to consider is the roof pitch—the angle or slope of your roof. The pitch not only affects energy production but also influences mounting methods, safety, and aesthetics.

So, what is the minimum roof pitch for installing solar panels effectively?

Understanding Roof Pitch

Roof pitch is typically measured in degrees or as a ratio (like 4:12, meaning a 4-inch rise for every 12 inches of run). A flat roof has a pitch of 0–5°, while a low-slope roof is often anything under 15°.

The Ideal vs. the Minimum

Ideally, solar panels should be installed at an angle that matches the latitude of your location for maximum year-round efficiency. However, panels can still function well at lower angles. The minimum practical roof pitch for fixed solar panels is around 5° to 10°.

At angles below this range:

-

Water and debris may not easily run off.

-

Energy generation can decline if snow or dirt accumulates.

-

Additional racking or tilt frames may be needed to improve the panel angle.

Solutions for Low-Pitch or Flat Roofs

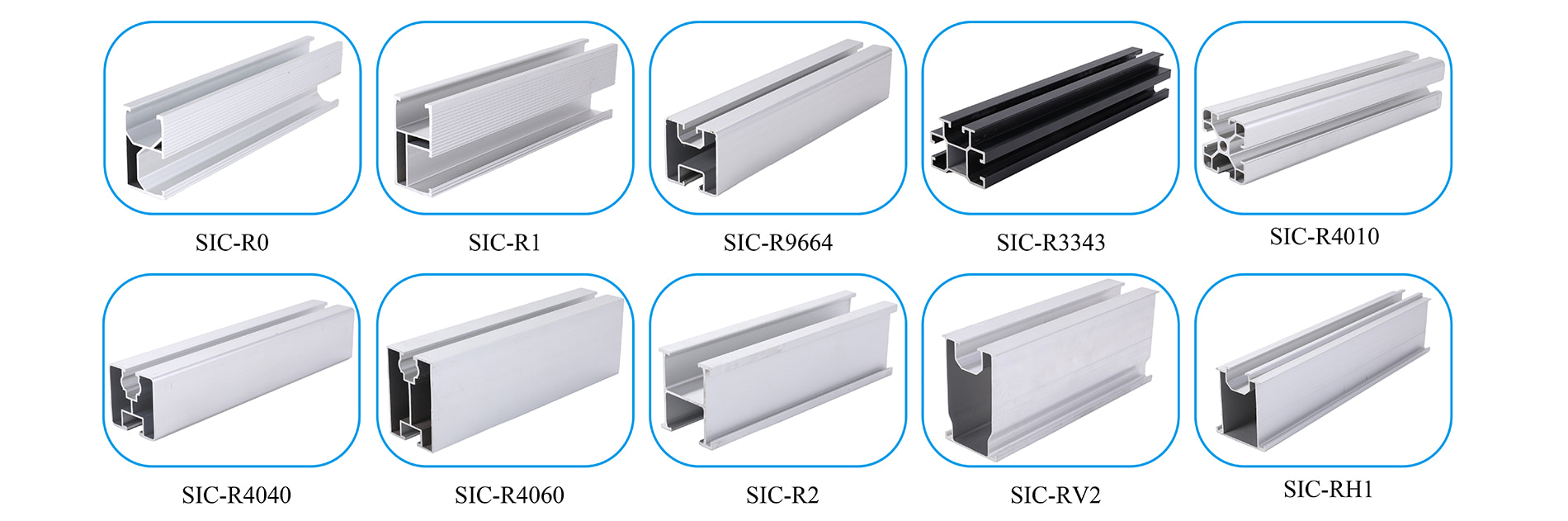

If your roof pitch is minimal or flat, you’re not out of options. Specialized mounting systems can add the necessary tilt. This is where manufacturers like SIC Solar come in. Their flat roof racking systems are engineered to optimize panel angles while ensuring stability, drainage, and wind resistance.

Ballasted or adjustable tilt mounts are often used to achieve the desired angle without penetrating the roof surface—minimizing structural impact and installation complexity.

Other Considerations

-

Wind load: Low-pitched roofs may catch less wind, which can be a benefit in storm-prone areas.

-

Aesthetics: Tilted systems on flat roofs may be more visible, so aesthetics may factor into your decision.

-

Maintenance: A steeper tilt makes self-cleaning easier through rain runoff.

The minimum roof pitch for solar panels is generally 5°, but panels can be installed on even flatter surfaces with the help of elevated racking systems. What matters most is choosing the right mounting solution tailored to your roof type and location.

With the right equipment—like those offered by SIC Solar—you can enjoy efficient, reliable solar performance even if your roof doesn’t have a steep slope.