In recent years, as the world gradually shifts towards renewable energy sources like solar and wind power, energy storage systems have become increasingly important. These systems are used to store energy for later use, ensuring a reliable and continuous power supply even when sunlight or wind is insufficient. So, what exactly is an energy storage system, what is the best method for storing energy, and which is the most efficient? Let's explore these questions.

What is an Energy Storage System?

An Energy Storage System (ESS) is a device or technology used to store energy for later use. It works by converting electrical energy into a form that can be stored (such as chemical energy, mechanical energy, or thermal energy), and then converting it back to electrical energy when needed. Energy storage systems are particularly useful for balancing the fluctuations in renewable energy supply, as these energy sources (like solar and wind) are often affected by weather conditions.

Common energy storage methods include:

Battery Storage: Storing energy in chemical form is the most common energy storage method.

Pumped Hydro Storage: Using the principle of hydropower, water is pumped to a higher elevation to store energy, and then released to generate electricity.

Compressed Air Energy Storage (CAES): Storing energy by compressing air, which is then released to drive turbines and generate electricity.

Thermal Storage: Storing energy in the form of heat or cold, typically using materials like molten salts, which can be released when needed.

Off-grid Solar Energy Storage System: A Solution for Remote Areas

The Off-grid Solar Energy Storage System is an ideal choice for areas that are far from the power grid. This system combines solar panels with energy storage devices, providing reliable power in the absence of a grid. Not only is this system environmentally friendly, but it also ensures a stable power supply for users in locations where grid electricity is unavailable.

Such systems are especially suitable for rural, mountainous, or remote areas. With the energy collection capability of solar panels and the efficient storage capacity of batteries, the Off-grid Solar Energy Storage System enables users to achieve energy independence, reducing reliance on external power supplies.

All-in-One Residential Storage System: A Convenient and Efficient Home Energy Solution

As energy demands continue to rise, the All-in-One Residential Storage System has become a preferred solution for home solar applications. This system integrates solar panels, storage batteries, inverters, and energy management systems into a single unit, providing homeowners with a comprehensive energy storage solution.

The advantages of the all-in-one system include:

Simplified Installation: Compared to traditional systems, users only need to install one device, reducing complexity.

Space Efficiency: The integrated design saves space, making it ideal for residential use.

Smart Management: These systems often come with intelligent battery management systems (BMS), which optimize battery usage and monitor battery health.

The All-in-One Residential Storage System is perfect for homeowners who want to install a solar storage system in their homes, helping reduce energy consumption while increasing energy self-sufficiency.

What is the Best Energy Storage System?

The "best" energy storage system depends on specific application needs, efficiency, cost, scalability, and environmental impact. However, lithium batteries are currently the most widely used and versatile energy storage solution, especially for residential and commercial applications.

The advantages of lithium batteries include:

High Efficiency: Typically, the discharge efficiency is over 85%, effectively reducing energy loss.

Compact Size: Flexible installation options, especially suitable for homes.

Cost-Effective: Ideal for short to medium-term energy storage needs, with costs continuously decreasing in recent years.

For large-scale storage, pumped hydro storage remains the most widely used method due to its ability to store large amounts of energy, though it requires specific geographical conditions.

What is the Most Efficient Energy Storage Method?

Energy storage efficiency refers to how much of the stored energy can be retrieved when needed. Based on efficiency, lithium batteries remain the most efficient energy storage method, typically achieving over 90% discharge efficiency. This means lithium batteries retain minimal energy loss during storage.

The efficiency of other storage methods is as follows:

Pumped Hydro Storage: Efficiency is about 70-80%, which, although lower than lithium batteries, still has significant advantages for large-scale energy storage.

Compressed Air Energy Storage (CAES): Efficiency is around 70-80%, but its performance can be influenced by geological conditions and technology.

What is the Most Promising Energy Storage Technology?

Looking ahead, the most promising energy storage technologies are those that can overcome the limitations of current systems in terms of cost, scalability, and environmental impact. The following technologies are considered to have great potential:

Solid-State Batteries: Solid-state batteries have the potential to revolutionize energy storage by offering higher energy density, better safety, and longer lifespans. Although they are still under development, they are seen as an important part of the future of energy storage.

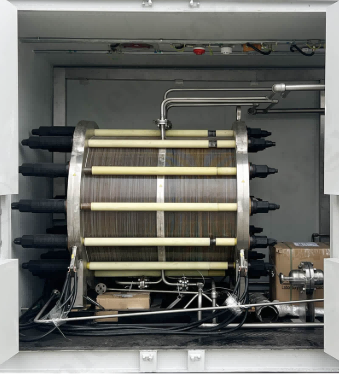

Flow Batteries: These batteries use liquid electrolytes and are expected to provide larger storage capacities and longer lifespans compared to traditional lithium batteries. Flow batteries also offer significant cost advantages, although they are still in the early stages of commercialization.

Hydrogen Storage: Hydrogen fuel cells represent an emerging energy storage method, particularly suited for long-term and large-scale energy storage. Hydrogen can be produced using renewable energy and stored in gas form, later converted back to electricity through fuel cells. While hydrogen storage has high potential, it still faces challenges in efficiency and infrastructure development.

Advanced Thermal Storage: Through materials like molten salts, thermal storage systems can store energy in the form of heat or cold and release it when needed. These systems have already been successfully used in large-scale solar power plants and have the potential to play a larger role in the future.

As the world transitions to renewable energy, energy storage becomes a crucial component. While lithium batteries are currently the most effective and widely used solution, emerging technologies such as solid-state batteries, flow batteries, hydrogen storage, and advanced thermal storage are rapidly gaining attention and hold the potential to improve efficiency and reduce costs.

Enecell, a renowned Solar Energy Storage System Manufacturer in China, provides integrated All-in-One Energy Storage Systems that combine inverters and lithium batteries. These systems are easy to install, have an elegant and simple design, and resemble home appliances when placed in a home, offering convenient and efficient solutions for residential energy storage.